We are honored to be featured in the esteemed "Engine Builder" magazine in May of 2017. In this interview Dave Weber, Owner of Modern Muscle Performance / ModernMuscleXtreme.com shares some of his secrets to success with the new 6.2L HEMI Hellcat Engine platform and taking it to new horsepower levels. Click the article link to view on their site: Hellcat 6.2L HEMI Engine

As Featured in Engine Builer Magazine:

If you talk to Dave Weber or have visited his shop, Modern Muscle in Martinsville, VA, then you already know what makes his engines special. His shop’s claim to fame is utilizing factory performance engines and applying innovative build techniques and premium parts to make them even better.

“This shop prides itself on getting as much as we can out of the factory parts,” Weber says. “This isn’t 1969 and it’s not a bunch of gray iron coming out of Michigan. It’s all good stuff. The casting techniques, the alloys, gasket technology, everything is so advanced it’s not the way it used to be.”

Modern Muscle likes taking and enhancing what Detroit has provided.

“It’s been really successful because we can take a performance engine out of Detroit that makes 485 hp and we can make 1,100 hp with it with crucial changes to pistons, rods, gaskets and some fasteners,” Weber says. “In a way it’s a claim to fame for us, but there are some people who don’t understand it and think it’s a short cut. That’s not the case at all – it’s a pretty premium build when it’s done.”

One particular engine package Modern Muscle does is a Hellcat upgrade. When you’re dealing with something like the Hellcat, it’s not your normal power upgrade. You basically have engines capable of 1,000 flywheel as they come from the factory. According to Weber, at the point of 850 – 900 wheel power, these engines start to come “unglued” due to a powder metal technology for the rod.

“It wasn’t meant to make that kind of power,” he says. “It’s a fantastic rod that will run forever at 800 hp or whatever it was designed for flywheel, but it’s not meant for how hard people want to push these engines.”

To take something from 500 hp and make someone happy at 800 hp is a whole lot different than going upwards from 1,000 hp. Those people are looking to get 1,200 – 1,500 hp.

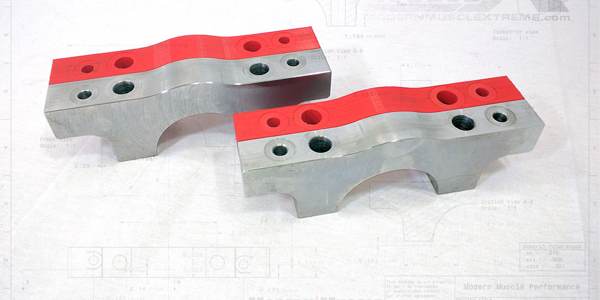

“On this build we are doing currently, we’ve developed a billet four-bolt with two cross bolts, so it’s a six-bolt cap for the center three,” he says. “Basically like the old HEMI, but with more fasteners. The factory Hellcat cap is a two-bolt with two cross bolts, so it’s kind of a four bolt. The reason for more fasteners is to tie up the block better for distortion, and we are getting to a power level that two main 12mm bolts aren’t going to get the job done, so we need to tie it into the webbing of the block better. We developed these six-bolt billet main caps, and there is enough material in the factory Hellcat block to be able to machine and have good support for it.”

From there, Weber says he upgrades to a 4” crank from Molnar because there is no reason to go into a motor like this and not try to increase the displacement.

“We can’t keep pushing a 3.580” crank and 6.200 to beyond 1,000 hp,” Weber says. “We need to add some displacement. So we add a 4” crank with a 2.100 GM rod journal. That’s about as much as we can stretch and still be able to get the packaging correct. I like the 4” with the 2.100 because it has overlap between the rod journal and the main. That overlap is what transmits all the power from the engine. When you fail or flex a crank it’s because there isn’t enough overlap. The last journal transmits every bit of power and shock from every cylinder. The overlap between a rod journal size and a main size becomes really important.”

The other thing the 4” crank allows Modern Muscle to do is keep some rod length in the motor. What’s real popular among people modifying the Hellcat is everybody wants the 4.26.

“The reason I chose not to add the additional stroke is the piston packaging becomes an issue with still leaving some rod length in the motor,” he says. “The factory rod length on that engine is 6.200. We are adding stroke, which changes the rod ratio, but what people are doing is adding stroke and reducing the rod length too, sort of like the old 400 Chevy, and it’s not happy. It’s going to push on the walls harder, it’s going to wear the pistons more and pull the pistons out of the bottom of the bore. There are a lot of little negatives, and they are little, but a negative is a negative.”

Weber and his team at Modern Muscle work with Mahle pistons to keep a really good piston package for the Hellcat upgrade as far as compression distance, ring pack, how far the ring is down, crown thicknesses, and everything that needs to be considered when trying to build a 1,500 hp engine with a 300 shot.

“Raw 1,500 hp on boost and then 300-400 shot is what Mahle used to design the piston,” he says. “We were able to keep the compression distance and maintain compression ratio we needed for that application and still fit the 6.200 Molnar rod.”

Mahle happens to be the original manufacturer and did all the engineering on the factory Hellcat piston. The motorsports crew who helps Modern Muscle with the design of components are the same guys who did the Hellcat design.

For this Hellcat engine, Weber upgrades the fasteners, the rods and the crank. One of the areas he maintains the factory part is with the heads.

“The Hellcat heads are a better material than a normal cast head,” he says. “They are more of an aftermarket head material and alloy. We reuse those heads, but we do rework them. We do chamber work and soften the quench and taper the quench to the center. This makes it less prone for detonation and things like that. It makes it a more efficient chamber.”

Between the head and the block Modern Muscle uses the Cometic MLX series gasket.

“Kevin Kisner has been great working with us,” he says. “The MLX tooling is set up for a certain bore size, which is different than other types of gaskets.”

Camshaft-wise, Modern Muscle works closely with Comp Cams and is sure to maintain a hydraulic roller.

“For me, at this level with the amount of boost and things that are available to us with these engines, it’s still about seat timing,” Weber says. “They don’t need 700 lift. It’s about getting the proper seat timing and the proper load, and we’re still able to hit some impressive numbers with the hydraulic roller.”

Modern Muscle does all its own CNC head work in-house as well as all the cap installations. However, Weber has a buddy in town who handles the shop’s honing and decking.

No matter what you’re doing to the engine, you have to keep in mind the amount of horsepower you’re looking to add and what needs to remain in the Hellcat engine and be upgraded to produce a durable, successful build.

“You’re starting point is 1,000 hp, it’s not your finishing point, and there are a lot of things that you have to pay attention to that the factory provided you and you better not pull back on them,” Weber says. “We set up the engine so that it is capable of 1,400-1,500 hp. On this particular Hellcat engine our goal is 1,000 hp at the wheel, which would be around 1,200 hp. We top it off with some Royal Purple oil and give it hell.”

International Order Notice:

International Order Notice: