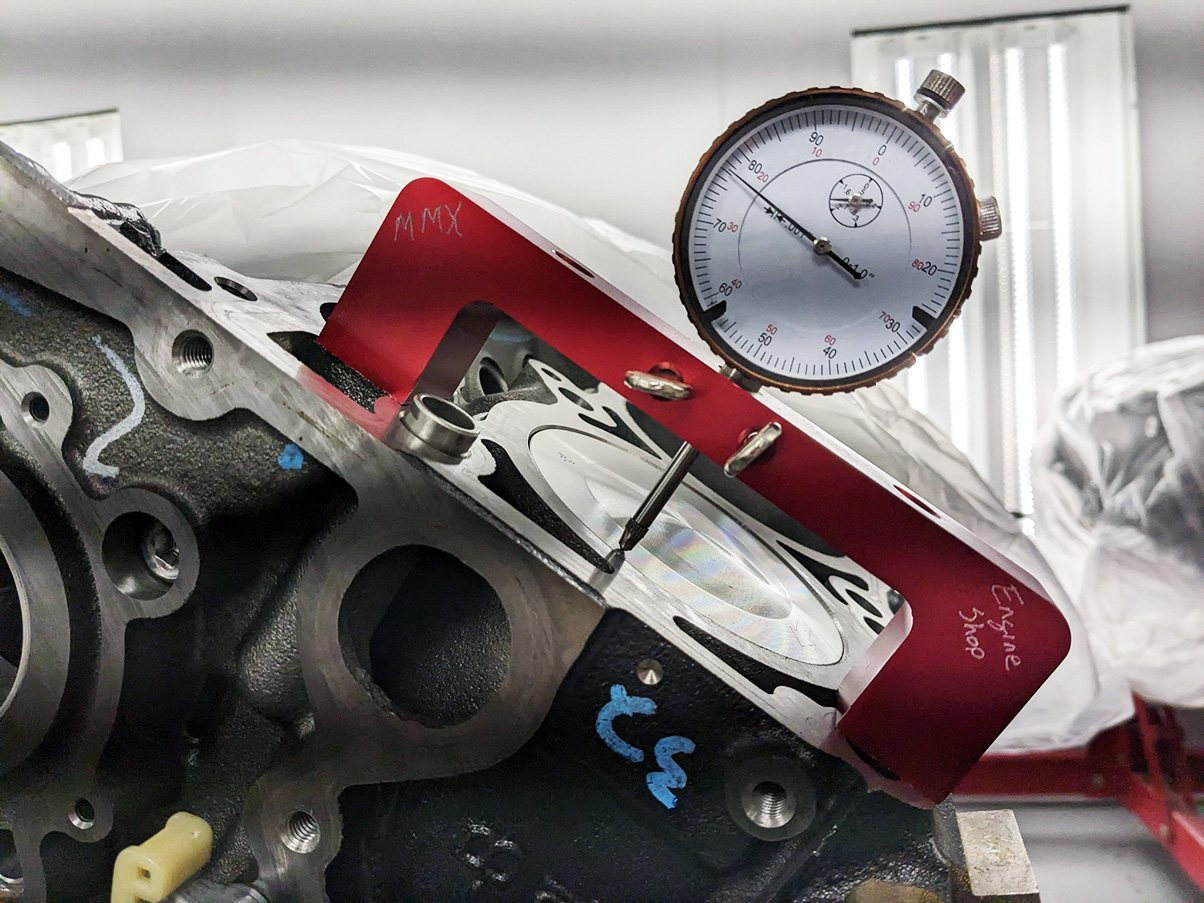

HEMI Engine Building Tech by Byron Walker of MMX

When building a stroker engine, or any engine for that matter it is important to check piston deck height (The distance from the deck surface of the block, to the top of the piston). Often times, piston and rod combinations or stroker rotating assembly kits are specified out to be at zero deck (Piston even with the deck surface of the block).

This is particularly an issue with 5.7 HEMI engines, because they come factory with .027 compressed thickness head gaskets. The factory does this because their piston and rod combination lands .020-.025 below deck, allowing for adequate quench clearance.

Using the typical 5.7 stroker parts combo of a 4.050 crank, 6.125 rod, and a 1.095 CD piston, the piston will be at zero deck on a NON VVT block, and roughly .005 below deck in a VVT block.

.040 is the minimum recommended clearance to run between the piston and cylinder head. If you install a .027 head gasket on a 5.7 base stroker, you will have only .027-.032 clearance between the cylinder head and the piston. This is also assuming your machine shop did not deck the block at all, which would make the situation worse. When this is run, it not only sounds terrible (with the pistons smacking the head) it will often take out rod bearings as it causes the oil clearance to be taken up every time the piston smacks the head.

If you are assembling an engine at home, remember that YOU and only YOU are responsible for all measurements related to an engine build. Don't Assume that parts are correct just because they were purchased in a kit, or that certain stock parts will still work on your engine, as it is NO LONGER STOCK.

International Order Notice:

International Order Notice: